6200 CE Zirconia Ceramic Deep groove Ball Bearing

Ceramic is a glass like surface it has an extremely low coefficient of friction and is ideal for applications seeking to reduce friction and heat. Ceramic balls require less lubricant and have a greater hardness than steel balls which will contribute to increased bearing life. Thermal properties are better than steel balls resulting in less heat generation at high speeds and bearing capable of handling extremely high temperatures. Full Ceramic bearings can have a retainer or full complement of balls, retainer materials used are PEEK and PTFE.

Ceramic ball bearings use ceramic balls. Ceramic balls weight is less than steel balls, depending on size. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter ball allows the bearing to spin faster, and uses less energy to maintain its speed.

6200CE detail Specifications

Construction:Single Row

Seal Type:Open

Ring Material:Ceramic Zirconia/ZrO2 & Silicon Nitride/Si3N4

Ball Material:Ceramic Zirconia/ZrO2 or Silicon Nitride/Si3N4

Cage Material:PEEK

Seals Material :PTFE

Limiting Speed :16800rpm

Weight: ZrO2 / 0.025 kg ; Si3N4 /0.013 kg

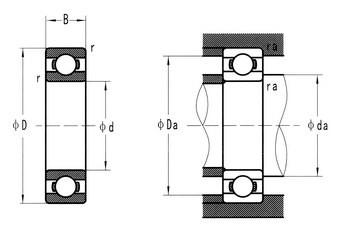

Main Dimensions

Overall Dimension

d:10mm

D:30mm

B: 9mm

Mounting Dimension

r min.:0.6mm

da min.:14mm

da max.:16mm

Da max.:26mm

ra max.:0.6mm

Dynamic load ratings(Cr):1.02KN

Static load ratings(Cor): 0.48KN