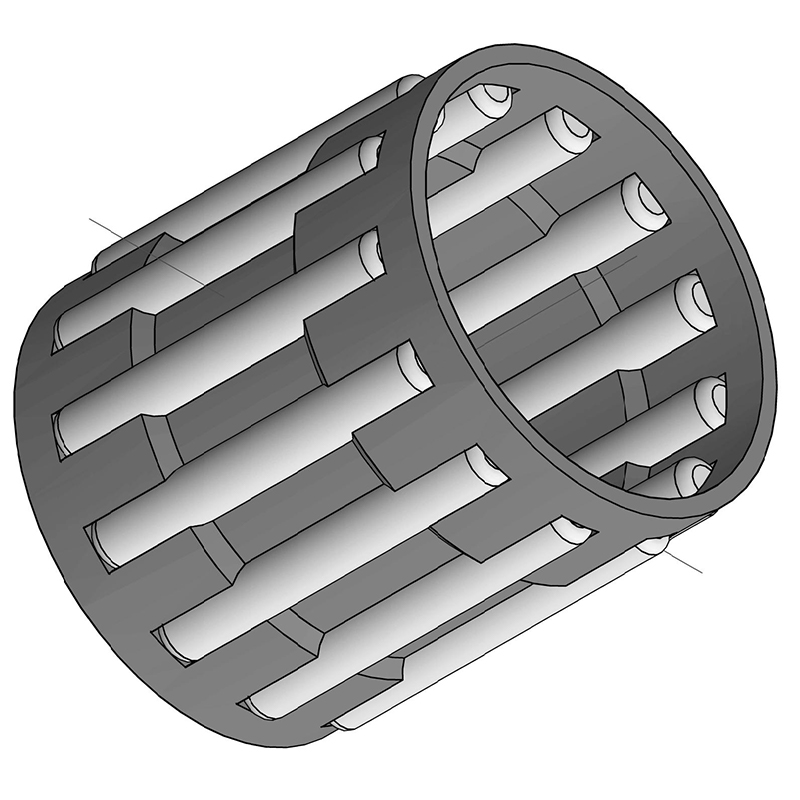

K10X13X16 Needle roller bearings and cage assemblies

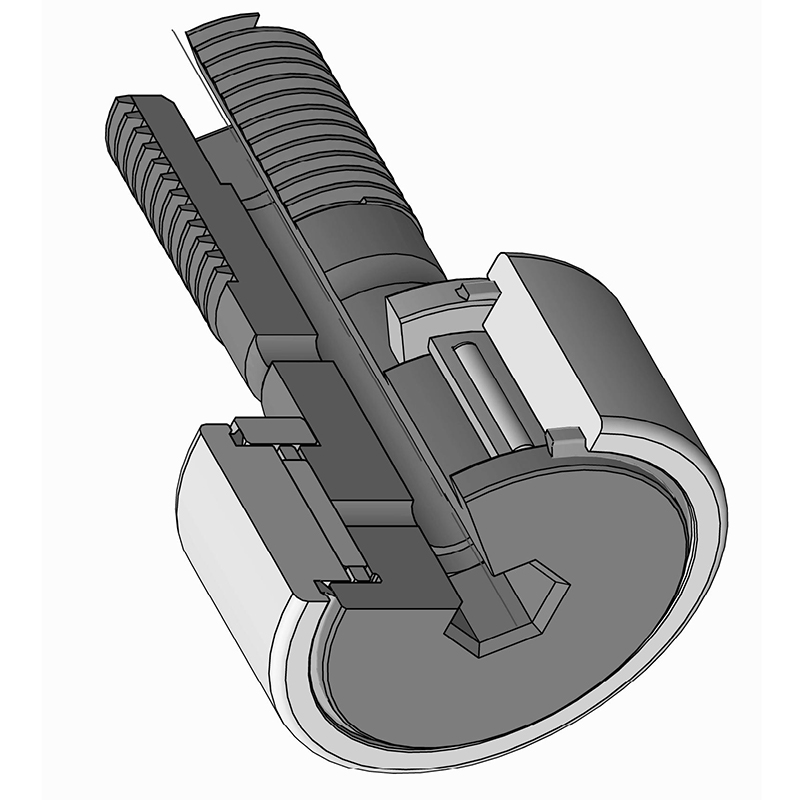

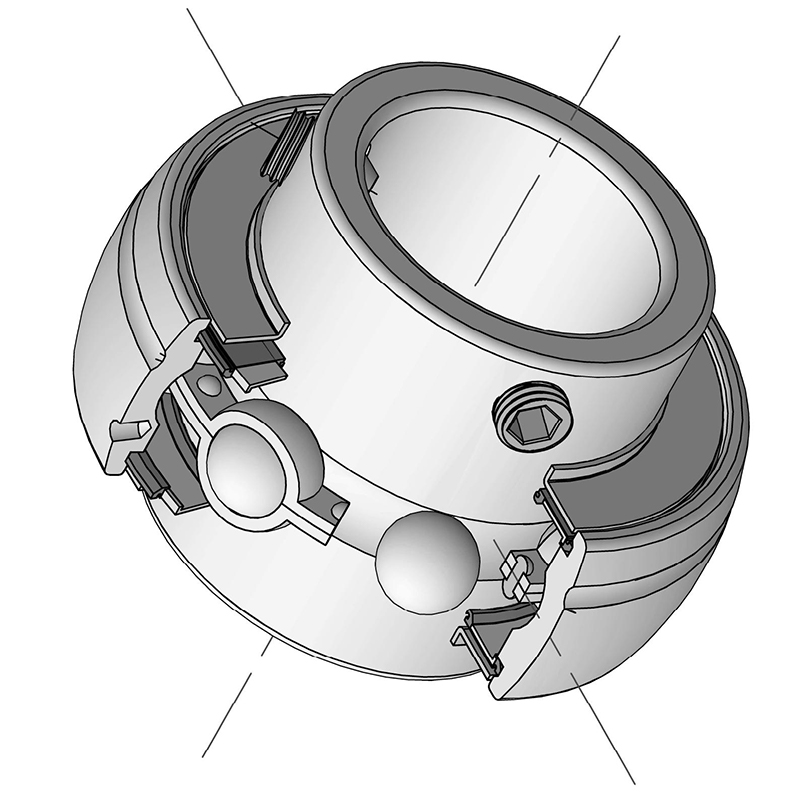

Compared to ball bearings and ordinary roller bearings, needle bearings have a greater surface area in contact with the races, so they can support a greater load. They are also thinner, so they require less clearance between the axle and the surrounding structure.

Features of Needle roller bearings and cage assemblies

1.Lowest cross section among rolling bearings

needle roller and cage assemblies are self-contained, ready to mount bearings. In applications where the shaft and housing bore can serve as raceways, the assemblies can be used to create bearing arrangements that require minimal radial space.

2.High load carrying capacity

Owing to their large number of rollers, needle roller and cage assemblies have a high load carrying capacity.

3.High stiffness

Because of their large number of small-diameter rollers, needle roller and cage assemblies have high stiffness.

Applications of Needle roller bearings and cage assemblies

Automotive transmissions, air-conditioner compressors, bulldozer blades, overhead traveling cranes, gearboxes, machine tool spindles, copying machines and so on.

Radial needle roller and cage assemblies can support high radial loads and allow high speeds. They combine the load carrying capacity advantages of full complement needle roller bearing arrangements with the speed advantages of a cage bearing and are easy to mount.

K10X13X16 Needle roller bearings and cage assemblies detail Specifications

Material:52100 Chrome Steel

Construction:Single Row

Cage Material:PA66

Limiting Speed:23200 rpm

Packing: Industrial packing and single box packing

Weight:0.004 kg

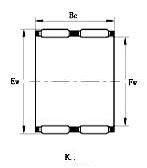

Main Dimensions

Diameter under rollers(Fw):10mm

Outside diameter roller complement(Ew): 13mm

Width needle roller and cage assembly(Bc):16mm

Dynamic load ratings(Cr): 5.68KN

Static load ratings(Cor): 7.44KN