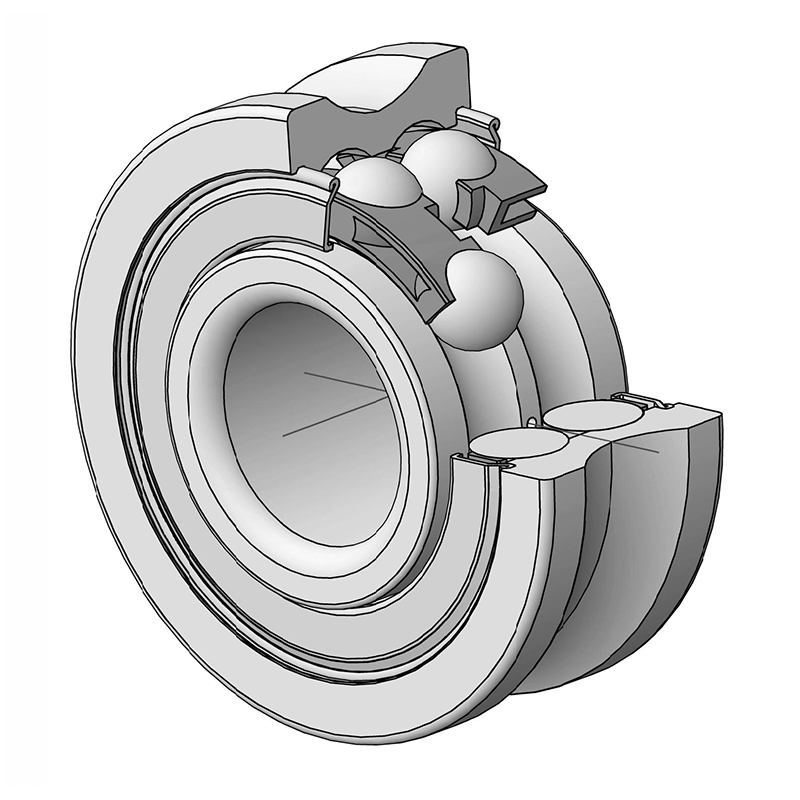

LFR5302-10-2Z Track Roller Bearing With Profiled Outer Ring

There are two contact points between the roller and track, so the contact function is favorable.

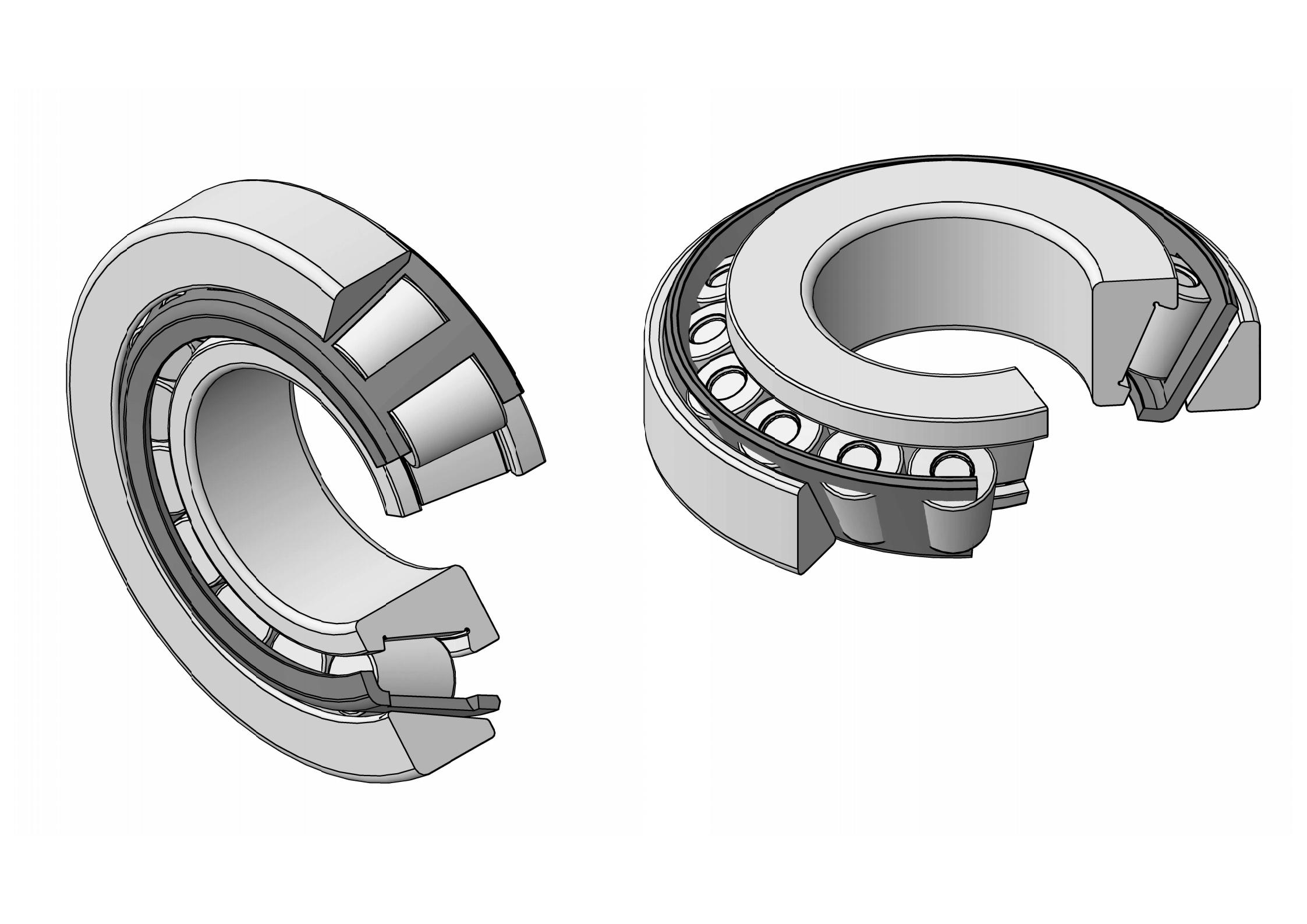

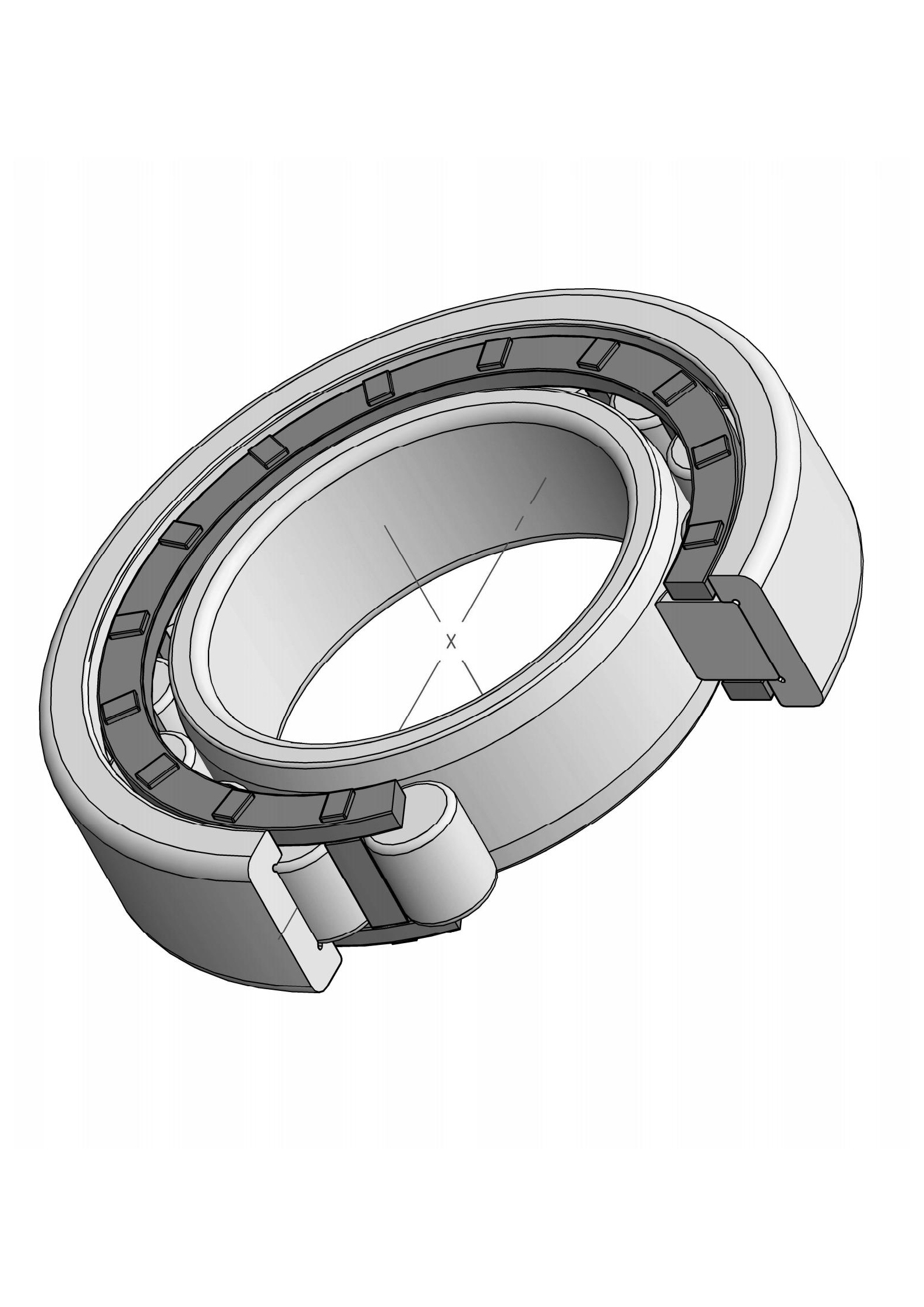

Rollers feature double row angular contact ball bearing in its internal structure design and a thick-walled outer ring, so rollers can accommodate higher loads.

Rollers are made of high-quality bearing steel, processed by heat treatment and precision grind, and are filled with a long service life, high-grade and multi-purposes grease

Features of Track Roller Bearing With Profiled Outer Ring

1. High allowable speed, low resistance, long service life

For series LFR rollers, the surface profile of the outer ring is designed as the GOTHIC ARCH.

When rollers running, there are two contact points with an angle 60 degrees between the roller and track. So the friction resistance is low and the load is in equality, thus avoiding the stresses concentration and edge effect caused by the error from installation and manufacture, making the track system has the characteristics of high speed, low energy consumption, long service life and minimum noise level.

2. Easy installation

As rollers assembled the concentric or eccentric pivot, installation can be made convenient. To adjust the eccentric one's eccentricity, these rollers can get the fitting preload

LFR5302-10-2Z detail Specifications

Material:52100 Chrome Steel

Guide Roller Type:Track

Seal type:ZZ

Seal material: Metal Shieds

Construction:Double Row

Lubrication:Great Wall Motor Bearing Grease2#,3#

Temperature Range: -20°to 120°C

Weight:0.17kg

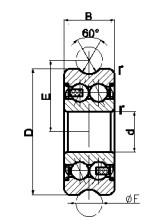

Main Dimensions

Outer Diameter (D):47mm

Tolerance for outer: -0.011mm to 0mm

Inner Diameter(d):15mm

Tolerance for inside:-0.008mm to 0 mm

Width(B):19mm

Tolerance for width :-0.12mm to 0mm

r min. :0.6mm

E:26.65mm

F:10mm

Dynamic load ratings(Cr):16.2KN

Static load ratings(Cor):9.2KN